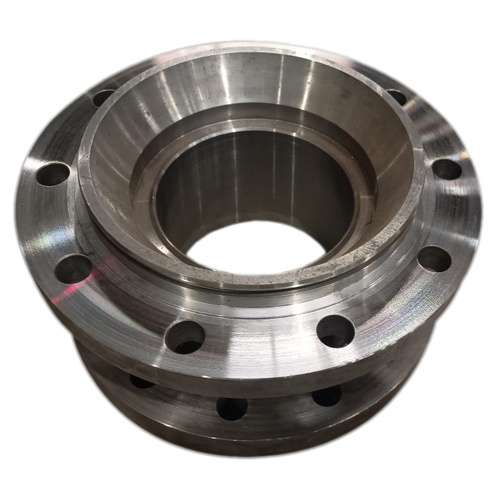

पाइप कपलिंग

उत्पाद विवरण:

- कंट्रोल सिस्टम Manual lever, gear operator, or pneumatic/electric actuator

- वाल्व का प्रकार Butterfly Valve

- वाल्व का आकार Different sizes available (standard, customized)

- विशेषताएँ Corrosion resistant, robust construction, interchangeable disc and seat, compact design

- कनेक्शन का प्रकार Wafer, Lugged

- स्ट्रक्चर

- एप्लीकेशन Industrial piping systems, water treatment plants, HVAC, oil & gas, chemical industries

- अधिक देखने के लिए क्लिक करें

X

पाइप कपलिंग मूल्य और मात्रा

- 100

पाइप कपलिंग उत्पाद की विशेषताएं

- Up to 120°C (Standard)

- Wafer, Lugged

- Butterfly Valve

- Manual lever, gear operator, or pneumatic/electric actuator

- Different sizes available (standard, customized)

- Corrosion resistant, robust construction, interchangeable disc and seat, compact design

- DN40 to DN600 (1.5 to 24)

- EPDM, NBR, PTFE or as specified

- Not applicable for manual type; actuator types may use 24V, 110V, or 230V as required

- Industrial piping systems, water treatment plants, HVAC, oil & gas, chemical industries

- Stainless steel or carbon steel pin

- Ductile Iron/Nickel plated/GGG40

- Butterfly Valve Body

पाइप कपलिंग व्यापार सूचना

- प्रति महीने

- दिन

उत्पाद वर्णन

Acclaimed for its durability and grandiose engineering, this butterfly valve body has consistently received favorable reviews from professionals worldwide. With a brilliant, epoxy-coated finish offering corrosion resistance, it meets IS 13095, EN 593, and API 609 standards. Available in various thicknesses and sizes (DN40DN600), its robust, majestic construction fits industrial piping, water treatment, HVAC, oil & gas, and chemical industries. Wafer type, suitable for manual or actuator control, features interchangeable discs and EPDM, NBR, or PTFE seals. Enjoy superb reliability and a hot deal for modern infrastructure needs.

Exceptional Performance and Versatile Applications

Used by industry leaders in sectors like water treatment, chemicals, oil & gas, and HVAC, this butterfly valve body is prized for its corrosion resistance, robust build, and compact design. Its application is straightforwardinstall between standard flanges and control manually or via actuator. The interchangeable disc and seat, along with various handle material options, ensure flexibility and ease of maintenance, making this valve a reliable solution for demanding industrial environments.

Domestic Market Reach and Quality Assurance

Serving as a reputable distribution and export hub in India, this butterfly valve body comes with clearly defined outlay options including sample policies for initial valuation. It is meticulously packaged to ensure product integrity during transit. Certified according to API 598 and EN 12266-1 testing standards, every unit reflects the companys commitment to superior quality and reliability. Customizations and prompt support ensure a seamless experience for domestic clients across markets.

Exceptional Performance and Versatile Applications

Used by industry leaders in sectors like water treatment, chemicals, oil & gas, and HVAC, this butterfly valve body is prized for its corrosion resistance, robust build, and compact design. Its application is straightforwardinstall between standard flanges and control manually or via actuator. The interchangeable disc and seat, along with various handle material options, ensure flexibility and ease of maintenance, making this valve a reliable solution for demanding industrial environments.

Domestic Market Reach and Quality Assurance

Serving as a reputable distribution and export hub in India, this butterfly valve body comes with clearly defined outlay options including sample policies for initial valuation. It is meticulously packaged to ensure product integrity during transit. Certified according to API 598 and EN 12266-1 testing standards, every unit reflects the companys commitment to superior quality and reliability. Customizations and prompt support ensure a seamless experience for domestic clients across markets.

FAQs of butterfly valve body:

Q: How does the epoxy coating enhance the valves performance?

A: The epoxy coating provides excellent corrosion resistance, protecting the butterfly valve body from harsh chemicals, moisture, and environmental wear, thereby increasing its longevity and performance in demanding applications.Q: What industries commonly use this butterfly valve body?

A: This valve body is widely used in industrial piping systems, water treatment plants, HVAC systems, oil and gas facilities, and chemical processing industries due to its robust construction and versatile sealing options.Q: Where can the butterfly valve body be installed?

A: It can be installed in pipelines conforming to EN, ASME, or IS standards using its wafer or lugged connection, making it suitable for both new projects and retrofitting in existing systems.Q: What is the process for choosing the right port size and disc material?

A: Customers should assess media type, pressure requirements, and temperature range, then select a port size (DN40 to DN600) and disc material (ductile iron, nickel-plated, or GGG40) best suited to their systems needs.Q: What benefits does the interchangeable disc and seat design offer?

A: The interchangeable disc and seat design allows for quick replacements and maintenance, reducing downtime, and enabling cost-effective, long-term operation.Tell us about your requirement

Price: Â

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

मोबाइल number

Email

जांच भेजें

जांच भेजें एसएमएस भेजें

एसएमएस भेजें मुझे निःशुल्क कॉल करें

मुझे निःशुल्क कॉल करें